Max PCB size:450mm x 350mm

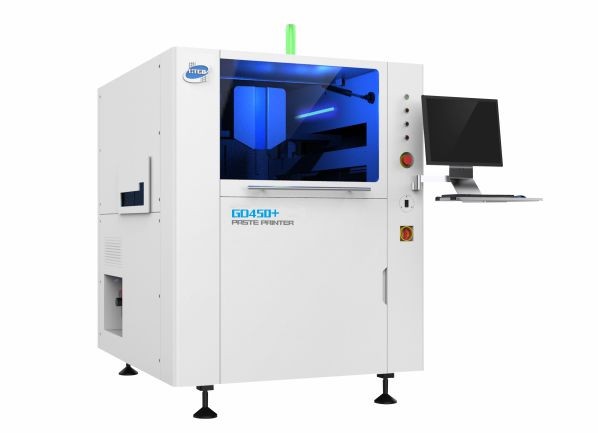

Voltage: 220V

Dimension: 1140mmx1400mmx1480mm)

Weight:1000Kg

SMT Stencil printer GD450+

Specifications:

The whole machine is fully controlled by servo system;

Automatic pressure feedback system;

Multifunctional image processing system;

Precise PCB transportation system;

Intelligent PCB holding device;

Automatic steel mesh positioning module;

Automatic and effective steel mesh cleaning system;

User-friendly operation interface;

PCB Parameter | |

Max PCB size (X x Y) | 450mm x 350mm |

Min PCB size (Y x X) | 50mm x 50mm |

PCB Thickness | 0.4mm~14mm |

Warpage | Max. PCB Diagonal 1% |

Max PCB weight | 10Kg |

PCB margin gap | 3 mm(conveyor belt PCB/frame touching width) |

Max bottom gap | 15mm |

Conveyor Speed | 1500mm/s(Max) |

Converyor height | 900±40mm |

Conveyor direction | L – R、R – L、L – L、R – R |

Conveyor method | Single rail |

PCB fixing method | Software adjustable pressure elastic side pressure (options: 1, bottom holistic suction vacuum;2, bottom multi-point area vacuum; 3, edge locking substrate clamping) |

PCB support Method | Magnetic thimble,equal high block,vacuum suction cavity(option:Grid-Lok) |

Printing Parameter | |

Printing head | Linear motor type close loop printing head |

Stencil frame size | 370mm x 470mm~737 mm x 737 mm |

Max printing area (X x Y) | 450mm x 350mm |

scraper type | steel scraper/rubber scraper(45°/55°/60) |

scraper length | 220mm~500mm |

scraper height | 65±1mm |

scraper thickness | 0.25mm Diamond-like carbon coating |

Printing method | Single or dual scraper |

Mould release length | 0.02 mm 至 12 mm |

Printing | 0 ~ 200 mm/s |

Printing Pressure | 0.5kg -10Kg |

Printing length | ±250 mm(from center) |

Cleaning system | |

Cleaning method Vacuum Dry Cleaning-Vacuum Wet Cleaning-Dry Cleaning (Programming Control) | |

Cleaning direction forth-back,Back and forth cleaning (programmed control) | |

Camera Parameter | |

Imaging area (FOV) | 6.4mm x 4.8mm |

Platform adjustment range | X,Y:±7.0mm,θ:±2.0°. |

Datum point type | Standard shape reference point (see SMEMA standard), pad/hole |

Camera System | Single camera, up/down single imaging vision system, geometric matching positioning |

Function Parameter | |

Repetitive accuracy of image calibration | ±10.0um @6 σ,Cp more than 2.0 |

Printing Repetition Accuracy | ±20.0um @6 σ,Cp more than 2.0 |

Cycle time | Less than 7s |

Product changing time | Less than 5 mins |

Equipment | |

Power Supply | AC220V±10%,50/60HZ,15A |

Air supply | 4~6Kg/cm2, 10.0mm tube |

Operation System | Windows XP |

Dimension | L(1140mm)x W(1400mm)xH(1480mm) |

Weight | 1000Kg |

Temperature humidity control system(Option) | |

Temperature Control Range | 23±3℃ |

Humidity Control Range | 45~70%RH4 |

Keywords:

Hanwha SM481 Plus Pick and Place Machine, Hanwha SM482 Plus Pick and Place Machine, Hanwha SM471 Plus Pick and Place Machine, Hanwha Decan S2 Plus Pick and Place Machine, Hanwha SM481 Plus SMT Assembly Line, Hanwha SM482 Plus SMT Assembly Line, Hanwha SM471 Plus SMT Assembly Line, Hanwha Decan S2 SMT Assembly Line.

Contact: Demi

Phone: +86 13632571161

E-mail: demi@flason.com

Add: No.94,Guangtian Road,Songgang Street,Bao an District Shenzhen China