Max PCB:450mm x 350mm

Printing repeatability:±20.0 um

Dimension:1152x141x1540mm

Weight: 1000KG

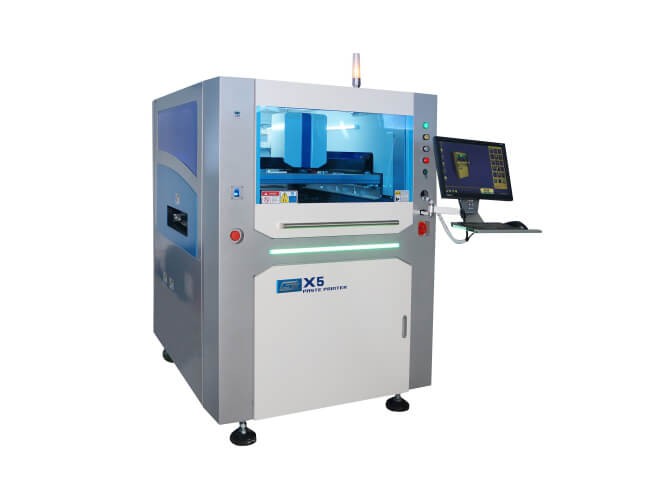

Inline SMT Stencil Printer X5

Specifications:

1.X5 dedicated adjustment platform

X5 special high-rigidity UVW module drive mechanism and inverted triangle Z-axis lifting mechanism effectively improve the stability of platform adjustment, realize ultra-fine transmission under micro-motion adjustment, and make the machine meet the requirements of higher precision printing. The platform height is automatically calibrated according to the PCB thickness setting, intelligent and fast, simple and reliable in structure; software adjustable pressure, elastic side pressure, edge locking and substrate compression. Adopt X5 special mathematical operation model, repeat accuracy ±10.0 microns@6 σ, Cp ≥ 2.0.

2. Programmable floating self-adjusting linear motor drives the printing head

Intelligent programmable settings, two independent direct-connected motor-driven scrapers, built-in precise pressure control system. , No need to take into account the change of squeegee blade type, length, weight or thickness. Programmable to achieve flexible printing process; designed for the different pressure of the front and rear squeegee and the stability of lifting, prevent the leakage of solder paste and the blade has a certain flexibility The clamping design of the squeegee, the pressure of the squeegee, the lifting speed, the printing speed, and the printing range are all software adjustable, and a variety of demolding methods are provided for customers to adapt to PCB boards with different tinning requirements, providing customers with a good printing Control platform.

3. Cleaning system

The new type of wiping system guarantees full contact with the steel mesh; three cleaning methods: dry, wet, and vacuum, and can be freely combined; soft and wear-resistant rubber wipers, clean thoroughly, easy to disassemble, and the length of the wiper is universal.

4. Highly adaptable steel mesh frame clamping system

Realize the printing of screen frames of various sizes, and can realize the rapid change of models in the production process; Y-direction automatic positioning.

5. Electronic control system

The use of self-developed modular integrated circuits is safe and easy to maintain; the industry's advanced industrial control system can be used to modify the parameters of the machine during the movement.

6. Image and light path system

New light path system—two ring lights and coaxial lights up and down, equipped with stepless brightness adjustment function, making various types

Mark points can be well recognized (including uneven Mark points), suitable for various types of PCBs with different colors, such as tin plating, copper plating, gold plating, tin spraying, and FPC. Four-way light source is adjustable, telecentric lens, stencil and PCB board are simultaneously illuminated up and down.

7. Simple and easy-to-use graphical Chinese/English operation interface

Use windows7 operating system and independently developed graphical man-machine interface: especially for the navigation effect of program files, which is convenient for all operators to quickly familiarize themselves with the operation; menu-style Chinese/English switching, operation log, fault record/fault self-diagnosis/fault analysis Reminder/light alarm and other functions make the operation simple and convenient.

8. 2D solder paste printing quality inspection and SPC analysis

The 2D function can quickly detect printing defects such as offset, less tin, missing printing, and even tin, and the detection points can be increased arbitrarily;

The SPC software can analyze the CPK index of the machine through the samples collected by the machine to ensure the printing quality.

X5 Specifications | |

PCB Parameter | |

Max PCB (X x Y) | 450mm x 350mm |

Min PCB(Y x X) | 50mm x 50mm |

PCB Thickness | 0.4mm~6mm |

Warpage | Max. PCB diagonal 1% |

Max PCB weight | 3Kg |

PCB adge clearance | Up to 3 mm |

Max bottom clearance | 20mm |

Conveyor Speed | 1500mm/S(Max) |

Conveyor height | 900±40mm |

Conveyor direction | L – R、R – L、L – L、R – R |

Conveyor Method | One Rail |

PCB Clamping Method | Programmable elastic side clamp + automatic adjustment of board thickness + edge locking substrate compression (options: 1, bottom overall suction cavity vacuum; 2, bottom multiple(Point partial vacuum) |

PCB Support Method | Magnetic thimble + contour block (option one, vacuum chamber; option two, dedicated workpiece fixture) |

Printing Parameter | |

Printing head | Suspended intelligent printing head (two independent direct-coupled motors) |

Frame size | 470mm x 370mm~737 mm x 737 mm |

Max Printing area(XxY) | 450mm x 350mm |

Squeegee type | Steel squeegee/rubber squeegee (angle 45°/55°/60° according to printing process matching selection) |

Scraper length | 300mm(Option 200mm~500mm ) |

Scraper height | 65±1mm |

Scraper thickness | 0.25mm Diamond-like carbon |

Printing Method | Single or double squeegee printing |

Demold length | 0.02 mm to 12 mm |

Printing Speed | 0 ~ 200 mm/S |

Printing Pressure | 0.5kg to 10Kg |

Printing Stroke | ±200 mm(from center) |

Camera Parameter | |

View Field (FOV) | 8mm x 6mm |

Platform Adjustment range | X:±5.0mm,Y:±7.0mm,θ:±2.0° |

Datum point type | Standard shape reference point (see SMEMA standard), pad/hole |

Camera System | Separate camera, up/down separate imaging vision system, geometric matching positioning |

Performance parameter | |

Repetitive accuracy of image calibration | ±10.0 um @6 σ,Cp or more than 2.0 |

Printing repeatability | ±20.0 um @6 σ,Cp or more than 2.0 |

Cycle time | Less than 7s(not including printing) |

Changeover time | Less than 5mins |

Equipment | |

Power | AC220V±10%,50/60HZ,15A |

Compressed Air | 4~6Kg/cm2, 10.0 diameter pipe |

Operation system | Windows 7 |

Machine size | L(1152mm)x W(1415mm)x H(1540mm) |

Machine weight | 1000Kg |

Keywords:

Hanwha SM481 Plus Pick and Place Machine, Hanwha SM482 Plus Pick and Place Machine, Hanwha SM471 Plus Pick and Place Machine, Hanwha Decan S2 Plus Pick and Place Machine, Hanwha SM481 Plus SMT Assembly Line, Hanwha SM482 Plus SMT Assembly Line, Hanwha SM471 Plus SMT Assembly Line, Hanwha Decan S2 SMT Assembly Line.

Contact: Demi

Phone: +86 13632571161

E-mail: demi@flason.com

Add: No.94,Guangtian Road,Songgang Street,Bao an District Shenzhen China