High Speed SMT Assembly line, with 2 Hanwha HM520 and 1 SM481 plus, the production speed can be around 200000 CPH. really fast for Mobile phone, LED light production, communication, LCD TV, STB, family cinema, vehicle electronics.

Hanwha HM520 SMT Assembly line

Specifications:

Hanwha HM520 SMT Assembly line

High Speed SMT Assembly line, with 2 Hanwha HM520 and 1 SM481 plus, the production speed can be around 200000 CPH. really fast for Mobile phone, LED light production, communication, LCD TV, STB, family cinema, vehicle electronics.

1. High Speed Hanwha HM520 pick and place machine.

Hanwha HM520 modular Chip mounter, it's Hanwha's first modular chip mounter, 890MM length.

890MM length ultra-small Chip mounter

80,000CPH(Rotary Head)

60,000 CPH (Piano Head)

LED products: 72,000 CPH (Rotary)

Automatic detection of pick and placing problem.

Automatically replenishing suction/mounting position and height deviation

Preventing LED defects caused by turning

PCB: Max (L) 750x (W) 580mm (optional)

Equipment size:2370x1440x890mm

Power AC200 / 208/220/240/380

Equipment weight:1605KG

2. Multifunction Hanwha SM482 Plus Pick and Place Machine

Hanwha SM482 is a Multifunction Pikc and place machine, deal with big components pick and placing.

1. Applicability to odd-shaped parts is reinforced.

2. Equipped with a head with one gantry and six spindles

3. Placement accuracy correction system(head offset,C/V offset etc.)

4. "Applicable to Max.740(L)x460(W)(Option)PCBs for long boards applied to LEDS and displays."

5. "It has improved actual producticity and placement quality by applying high speed and high precision electrically driven feeders."

6. Placement Rate:30,000CPH(Optimum)

7. Board Dimension(mm)):50(L)*40(W)~460(L)*400(W)

8. Option: 50(L)*40(W)~760(L)*460(W)

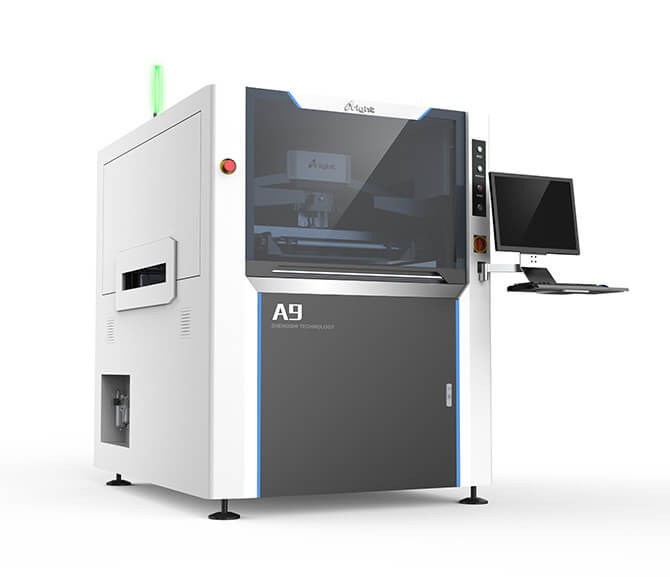

3. High Accuracy A9 SMT stencil printer.

A9 Solder Paste Printer Fully Automatic-Good Price! Good Quality! Good Service!High Accuracy smt stencil printer, which can satisfy the printing process requirements of 03015,0.25pitch high precision and high speed.

A Seriel SMT Stencil printer is high accuracy and high stability of the fully automatic printing machine vision,We followed in SMT industry is the development trend of production of a new generation of fully automatic printing machine with the international leading technology synchronous vision, visual processing of high resolution, high precision of the transmission system, suspension adaptive scraper.

Specification :

A Series High Precision Automatic Solder Paste Printer designed for high precision

steel mesh printing or stencil printing in SMT industry.

Printing PCB size:50mm x 50mm ~1200mm x 800mm;

PCB thickness: 0.4mm ~ 14mm

FPC thickness: ≦0.6mm (Excluding jig)

Applicable pitches of Components

SMT Components such as resistors, capacitors, inductors, diode and triode: 0201, 0402, 0603, 0805, 1206 and other specifications;

IC: support SOP, TSOP, TSSOP, QFN packaging, min. pitch 0.3mm; support BGA, CSP packaging,

min. ball 0.2mm;

Applicable PCB Types

Applicable to PCB types of mobile phone, communication, LCD TV, STB, family cinema, vehicle electronics,

medical power equipment, aerospace and aviation, besides general electronics products.

4. High output 6 meter 10 heating zones R10 SMT reflow oven

1. Windows XP platform, user friendly interface and easily swap between bilingual of English & Chinese.

2. Digital control system adopted with PLC and Modular circuit. Achieving high stability and repeatibility.

3. Intelligent diagnostic system (IDS) provides trouble remind, fault alert, list-out and SPC data record features.

4. Zone temperature and blower speed can be controlled Independently, to meet the high-precision requirements.

5. Effective heating zone length with uniform heat distribution.

6. Forced air cooling system with efficient cooling speed suits most kinds of lead-free soldering application.

7. PLC and PID closed loop control to achieve high precision temperature control.

8. Standard 10 couples of top and bottom zones with patented air management structure, more efficient hot air convection and faster thermal compensation.

9. The rail track is dealt with hardening process to make it more reliable.

10. Manual adjusted process track width whereas providing option of automatic by SPG gear motor.

11. Computerized controlled rail chain lubrication structure.

12. Powerful software system can save all settings and data printout capability.

13. Flux removal unit meet with environmental protection requirement.

14. Nitrogen structure is an option.

Keywords:

Hanwha SM481 Plus Pick and Place Machine, Hanwha SM482 Plus Pick and Place Machine, Hanwha SM471 Plus Pick and Place Machine, Hanwha Decan S2 Plus Pick and Place Machine, Hanwha SM481 Plus SMT Assembly Line, Hanwha SM482 Plus SMT Assembly Line, Hanwha SM471 Plus SMT Assembly Line, Hanwha Decan S2 SMT Assembly Line.

Contact: Demi

Phone: +86 13632571161

E-mail: demi@flason.com

Add: No.94,Guangtian Road,Songgang Street,Bao an District Shenzhen China